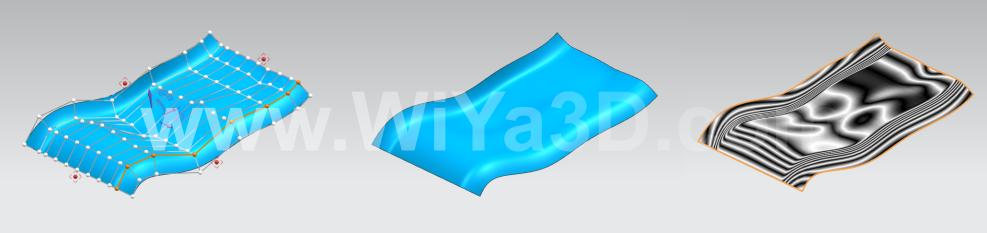

Archiving a aesthetically superior, high quality or nice look surface is key marketing point in current revolutionary industrial products. Whether it’s Automotive industry, industrial product developing field or any other fields, design engineer/product designer try to archive eye catching appearance for the design. There, A Class surface & Freeform surface play major role.

What is A Class Surface

A-Class surface is a term used in mainly to described the quality of freeform surface or combined set of freeform surfaces. While most of the A-Class/Class 1 surface modeling found in Automotive industry.

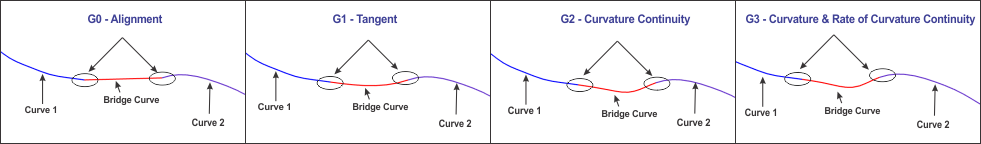

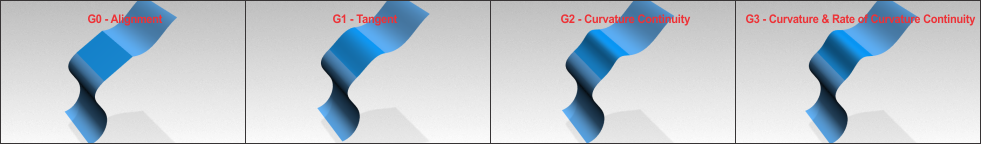

The main requirement of determining the surface/or joined surfaces A -Class, is to have surface Curvature Continuity. And for successful A-Class modeling , the surface patches joining need to have G2/G3 continuity & tight tolerance, which is more than 0.01 mm distance / 0.1 deg angle tolerating.

G0 – Surface Patches or Curve Share Same Simple Boundary

G1 – Surface Patches or Curve Share Same Boundary, While Maintaining Tangent Continuity

G2 – Surface Patches or Curve Share Same Boundary, While Maintaining Curvature Continuity

G3 – Surface Patches or Curve Share Same Boundary, While Maintaining Curvature Continuity & Rate of Change of Curvature or Curvature Acceleration

Class-A surface modeling is the creation of 3D surface data models to meet the aesthetic aspects and technological requirements of all visible interior and exterior surfaces. In surface modeling, Computer-aided industrial design applications are employed. Designers mainly use NURBS, Rhino 3D, Siemens NX and Autodesk Alias in automotive design.

What is Freeform Surfacing

Freeform surface modeling or surface, you will not find or adapt the perticular surface or partial area to any of regular/basic 3D modeling shapes like Flat/Plane, Conical, Torus, Cylindrical,Spherical . Design Engineer/Designer instead develop, total new surface with aesthetically superior, high quality for the application. The exterior/interior shapes of Automotive, Aerospace and industrial product development shapes -application are used freeform surfacing.

Important of A-Class & Freeform Surface

In design application, the A-class surface comprises freeform surfaces of high-standard quality and efficiency. This greatest challenge is to augment a model according to technical requirements (mechanical functionality and feasibility), the aesthetic quality (highlights, optic aspects, and continuity) and the product requirements which include modeling tolerance.

A Class & Freeform Surface, modeling bridges between engineering and design in the automotive industry, Aerospace Industry & Industrial Product to develop high-quality designs/shapes,that meet both the aesthetic and engineering requirements of models with this modeling technology.