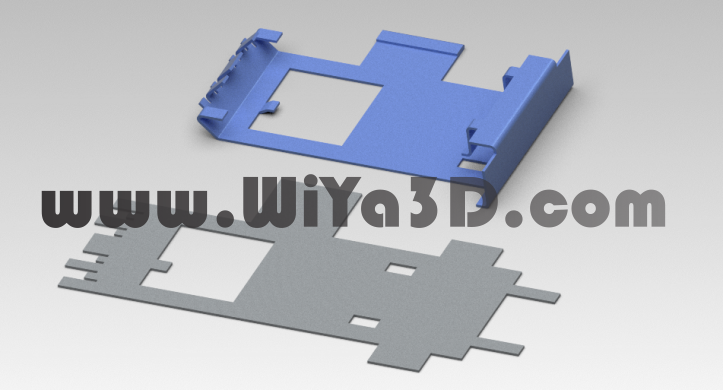

To get the absolute best from your sheet metal designs, you need to keep these basic tips in mind.

Managing different kind of blends

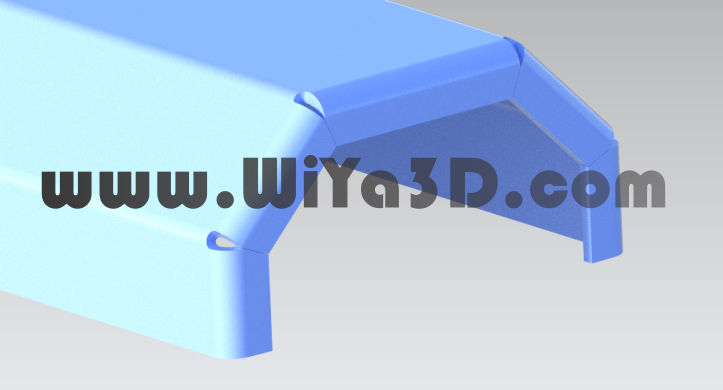

Features like gaps or spaces ought to be a multiple-time thicker from the curve range to the edge of the opening or opening to frame accurately. On the off chance that a plan calls for bent flanges, they should have a base outside-to-outside element of four material thicknesses. This permits the usage of standard instruments and framing forms that give the most minimal expenses and lead times. Exceptional devices or extraordinary meandering procedures moderate a section’s speed through a shop and commonly add the critical expense to a section.

When adding highlights to the divider, make the edges, at any rate, three material thicknesses from the twist range or these edges won’t shape accurately. While it might be okay to the originator that the edge disfigures, it can make issues an administrator attempting to shape that twist making it difficult to control and hold measurement reliably. If the twisting openings or space edges are alright, these highlights ought to be cut around the twist for best framing practices.

Counterbalances ought to be a base material thickness in tallness. When planning balance curves or run twists in Solid works, creators ought to have them at any rate material thickness in stature and comprehend that manufacture of balances of this nature is done in a press brake with balance devices that perform the two twists simultaneously. Gap and edge prerequisites with respect to the good ways from these curves still apply. Counterbalance twists ought to likewise be straight and not have bends, as this would require stepping or custom tooling that most shops stay away from. Standard counterbalance instruments will ordinarily follow in .060″ increases.

Tooling contemplation

Customary press-brake tooling, for instance, takes into account precision straight-line twists that can be fitted to practically any length and are ordinarily utilized on most created sheet metal parts. Keeping structures in this shape region considers the most reduced expense and quickest assembling occasions. This remains constant for highlights like round embellishes, connect spears, countersinks, expulsions, or different highlights. These can be normally done in a punch press and each exertion ought to be made to remain with standard sizes whenever the situation allows.

Precision sheet metal parts and machined parts are extraordinary. When planning precision sheet metal parts, note that, on account of the numerous procedures enveloped in making the parts, these parts are totally different from a machined part as far as what can be made and what resilience’s can be held.

Dealing with Tolerance

A typical issue to watch is structured with zero freedom between parts. This can make a resistance stack up, bringing about parts that won’t fit during getting together. At the point when congregations are demonstrated, the resilience of the parts ought to be represented in the dividing of the parts to be certain they will fit together when amassed.

Lethargic offsets

When structuring balances, fashioners ought to expect that the edges will be under 90 degrees on the two twists.

Little balances will normally be made as “apathetic” balances. This, for the most part, implies that each twist’s point in the balance is under 90 degrees. Sluggish balances assist fabricators with holding odd statures when required and the fabricators will generally recognize the counterbalances will be apathetic on their statement. As the tallness of the counterbalance expands, the point will move more like 90 degrees. At a tallness of multiple times the material thickness or more noteworthy, a producer will make the balance in two curves if a counterbalance instrument isn’t accessible at that stature for the pickle.

The dramatic finale

When the whole steel metal is made, the following product is wrapping up.

Powder covering is a decent completing alternative for steel or aluminum parts. Powder covering sheet metal parts is one of the sturdiest completing alternatives accessible to clients. It offers a scope of hues and surfaces to browse. At the point when applied in a way that covers all uncovered metal surfaces, it is great at averting oxidation. Powder covering can give a thick, thick finish that is ordinarily sturdier and longer enduring than customary paint alternatives with a more extended future too. Powder-covered surfaces are increasingly impervious to scratches, become dull, chipping, and chipping than different completions.

Zinc plating is the electrodeposition of a meager covering of zinc metal onto the outside of another metal, similar to sheet metal, to make a physical boundary that keeps rust from arriving at the first metal part. One of the most significant advantages of zinc plating is that it fundamentally builds the erosion obstruction of the part by shaping a boundary that really fills in as a conciliatory covering, implying that the zinc covering will consume rather than the first metal that it ensures. It is likewise a savvy covering that is more eco-accommodating than the cadmium coatings utilized before.

Chromate transformation covering of aluminum is a kind of coverage that is applied to passivate aluminum combinations, which will slow the development of white consumption. Chromate transformation coatings are regularly utilized on an electronic bureau or segment parts, and it tends to be generally called substance film. It additionally makes a decent introduction for aluminum parts to be painted.

With these tips, creators can model or deliver a more cost-productive part.