CAD-like Solidworks, Solidedge, Inventor, Fusion 360 ,..allows engineers & designers to design precision 3D components and aid in the manufacturing of these tools with reduced errors. How? CAD software can show you the actual features and functionality of an element before manufacturing it. This allows the operator to rectify mistakes, if any, before proceeding to the next level of production.

There are several common qualities across all professional CAD software.

Main Features & Capabilities of 3D CAD/CAE Software

-

3D Solid Modeling

-

Surface Modeling

-

2D Drafting

-

Capability to simulate and analyze

-

Electrical design

-

CAM integration or CAM add on/third Party

-

Data management features

-

Additive manufacturing

How Much Do You Have To Spend To Acquire A CAD

Typically, you can get professional 3D CAD software at $10,000. But, with between $500 and $5000, you can get any level CAD depending on the features it has. Here is a list of CAD programs that fit in mid-range engineering modeling software that you might need.

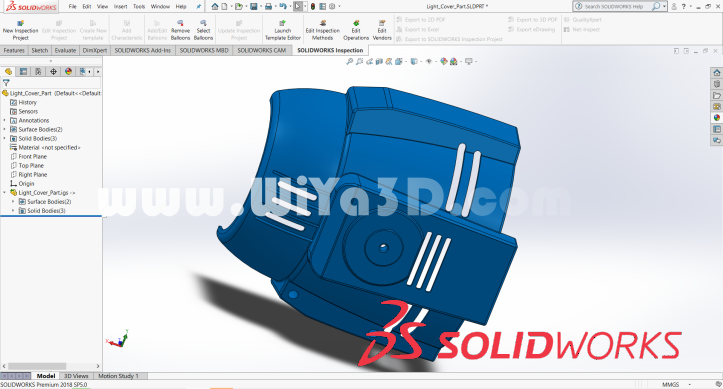

Solidworks

SolidWorks is a engineering CAD/CAE software that provide solution for product development for industrial application. it’s primary focusing solid modeling techniques based on parametric -feature based approach, rather than surface modeling in the 3D modeling context. Software is powerful software, that comes into market in standard, professional & premium features license to select and match the different product development requirement & applications.

Solidworks offer Key Features, Modeling Tools,

-

3D Solid Modeling

-

Large Assembly Design

-

Advance Sheet Metal Design

-

2D Drawing

-

Surface Modeling – although not powerful & lack in surface tools

-

FEA/CFD Analysis (Linear, Non-Linear, Static, Non Static, Dynamic,..)

-

Flow Simulation & Plastic Simulation

-

Motion Simulation

-

Mold Design

-

Bill of Materials,…..

In addition, add-in provide add on features as follows

-

PhotoView 360 – add -in create photorealistic image rendering for models

-

SolidCAM – add-in for CNC CAM Manufacturing

With Solidworks, you spend less time design & developing a product, due to it’s minimal learning curve & with millions of online free resources to master along with powerful modeling tools. And thus reduced cost within consistent & high quality product development cycle. Sometimes, Solidworks get crash & slow, when working with large assembly modeling and complex sketching.

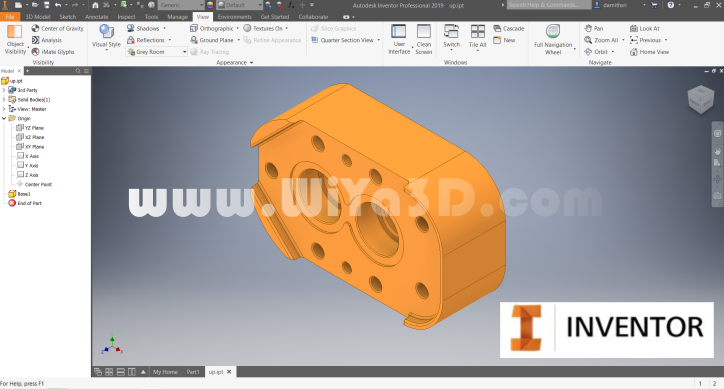

Autodesk Inventor

Autodesk Inventor is a 3D CAD software for mechanical design & development applications. Inventor also solid modeling software, which used to modeling & designing, simulate, visualize the product before actual manufacturing.

Inventor offer Key Features, Modeling Tools,

-

3D Solid Modeling

-

Large Assembly Modeling

-

Parametric Modeling & Freeform Modeling

-

2D Drawing

-

Automated Frame Design

-

Sheet Metal

-

Surface Modeling – although not powerful and lack in surface tools

-

FEA/CFD Analysis

-

Motion Simulation

-

Tube & Pipe Design

-

Rendering

In addition, add-in provide add on features as follows

-

SolidCAM – add-in for CNC CAM Manufacturing

Autodesk Inventor is a professional grade engineering CAD/CAE software, that can used in product/concept design & development projects. However in order to run full potential of Inventor it’s require to have powerful computer setup.

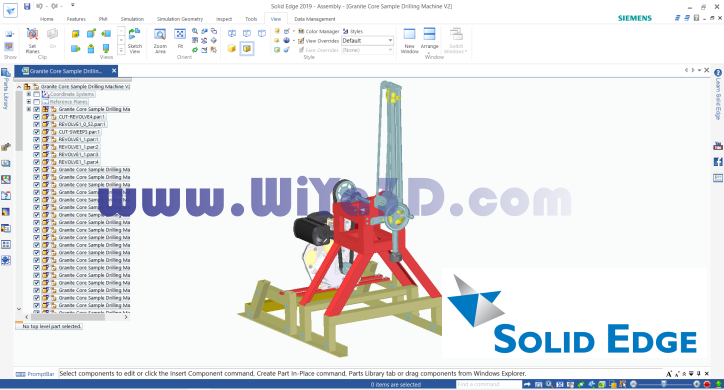

SolidEdge

SolidEdge is a product development software in all aspect and stage of the product design process. Synchronous technology or direct modeling technology make the SolidEdge stand out from other CAD packages and aid design & modeling speed up. Which is by allowing changes done based on history or without concerning history tree much.

SolidEdge offer Key Features, Modeling Tools,

-

3D Solid Modeling – Direct Modeling & Parametric Modeling

-

Synchronous Modeling

-

Assembly Modeling

-

2D Drawing

-

Sheet Metal

-

Surface Modeling – although not powerful and lack in surface modeling

-

FEA/CFD Analysis

-

Motion Simulation

-

Rendering

SolidEdge take little time to master with it’s tools, extra features & interface. And lack in 3D sketching capability But software run smoothly compare to others CAD packages even with large assembly parts/components. SolidEdge part library is lack specially fasteners and even thread has no actual threading rather than image representation in order to save file size.

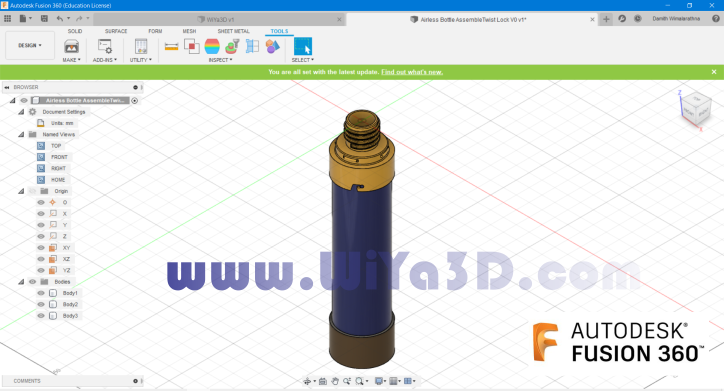

Fusion 360

Fusion 360 is Product Designing & Manufacturing software, integrated CAD/CAE/CAM in single platform. Software can be used to share complete design with team and modify the design without internet or not due to software cloud base access.Fusion 360 is a program that unifies planning, engineering, and manufacturing into one.

Fusion 360 offer Key Features, Modeling Tools,

-

3D Design & Modeling – Direct & Parametric Modeling

-

Assembly Modeling

-

2D Drawing

-

Sheet Metal Design

-

Surface Modeling – lack in surface modeling for complex surfaces

-

Mesh Modeling & Freeform Modeling

-

Collaboration

-

Static, Non Linear, Thermal, Buckling,.. Simulation

-

Rendering & Animation

-

CAM Manufacturing ( 2.5 – 3 Axis Milling, 4-5 Axix Milling, Turning,..)

Fusion 360 can be used as free license for individual, who are not going to use for commercial with almost of it’s full features.Although software can be used in some extend due to it’s some what simpler and still developing for designing. When it’s come to more complex design work rather than general product/concept & mechanical design the Fusion 360 has limitation to fulfill end design requirements and have to go for other CAD/CAE packages.

Conclusion

The above describing, engineering design – CAD software can get your work done in most of the task within the software.The difference is the time each takes to complete, how easy to model and the cost of each package. Also, you have to consider the user-friendliness of each package depending on your expertise such as some software is ideal for beginners, while others are such professionals.

Engineering design and other product designing are more straightforward as compared to previous years and mid range CAD software is up to the level handling most of the task.