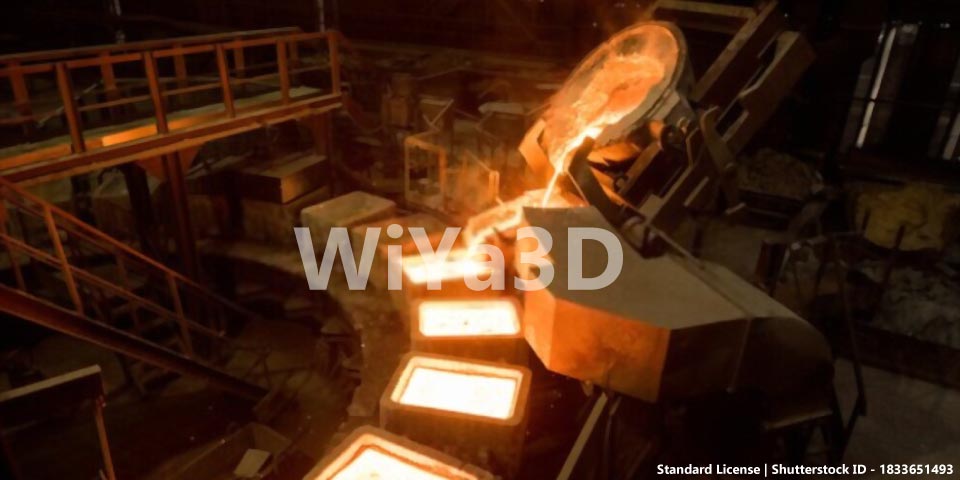

Basically casting technology is introducing & pouring the molten metal or material with fluid state into mold, which developed shapes to get the component needs. Then allowing it to harden inside the said mold and remove the item once the harden the metal/or material.

Fundamentals of Casting Technology

Open Mold

Products with relatively simple in complex and having at least flat surface are casting done with this open casting mold. The mold is made in in an open manner with top surface flat and those have ability to accept considerable surface shrinkage/distortion. The molten material introduce to this mold from top open & allow to solidify to get flat surface on top while other casting get the shape of the mold.

With this open casting technique due to molten material poured from top side and the oxide formed will float on top surface. Furthermore due to shrinkage may cause material to be sucked in from the top flat surface. However most of the time this top flat side with some depression, oxide marked later goes to product bottom side.

Closed Mold

In current most of engineering products/ requirements are done with rather complex shapes. There in order to get casting part as single cast it’s need to make the mold in such a way of two or more parts and put together to form cavity mold.

Thereby cavity is closed mold. Hence cavity mold need to consist with material pouring cup, air entrap removal riser process and provision to provide extra molten material to compensate for shrinkage like choke.

Design Consideration in Casting

When designing casting part/pattern or casting mold, the design engineer need to carefully analyze the casting process in order to get the product with require quality.

Parting Line – Selection of parting line may lead to reduce the number of mold plates for the casting old.

Component Modification – Sometimes with minor changes to the product/part can be reduce the complexity of the casting mold and cost reduction.

Section Thickness – Region/Section with more thicker in the casting mold get cool in slower. Therefore, special precaution need to take during design of casting part with more uniform thickness in all direction.

Stress Concentration – Stress concentration can be reduce mostly by removing sharp edges and curving/filleting those sectional region. However this may lead hotspot that thick areas get cool more slowly. Thereby more shrinkage defects happen. This both can balance and avoid by introducing core hole on such sections whenever possible.

Ribs – More ribs in product may cause significant shrinkage issues in casting mold. On the other-hand less ribs with less strength will lead crack in casting product.

Unsupported Areas – If the large area/region of casting part is unsupported, then it will lead wrap during the solidification of material. And which result in surface flatness and extra machining process for material removal.

Casting Pattern Allowances – During casting always cast product smaller than the cavity. Thus its always need to consider and design the part as well as casting cavity to incorporate those parameters.

Shrinkage Allowances – With casting product shape, material & pouring temperature, it need to consider the shrinkage allowances when design cast mold.

Machining Allowances – Almost all the casting cavity/mold & once casting done, the parts are machining in order to archive the product shape, complex surface detail, features and special surface finishing requirement. Hence foundry/or design engineer need to consider and need to allow allowances for machining, surfaces finishing, part holding/fixture attachment.

Draft Allowances – Another main consideration when designing casting mold is to ensure enough allowances for draft. Which use to easy or defect free removal of product from the casting mold.

Type of Casting & Casting Process

Sand Casting

Sand casting is the very common process that used to cast small to large parts with low to high level of technology with use of wide range of materials.

Mold is made out of using sand as main material and some clay and water as bonding the grain. Once pattern has been made for the product shape, the sand is packed around it. Normally mold is made in two or more pieces in order to remove the pattern. The sprue hole, pouring cup to pour molten metal, runner, gates, risers and other features added to the mold

Sand Casting technology Application

- Machine Beds, Frames

- Manhole Covers

- Gears & Pully

- Casing / Housing

- Impeller of pump, turbine

- Engine Block

Limitation in Sand Casting

In sand casting the molten material pouring under gravity. Therefore defects like blow hole, internal voids and insufficient fill can happen. Also in sand casting parts tend to have rough surface finish. Hence additional machining process need to follow archive dimensional accuracy & surface finishes.

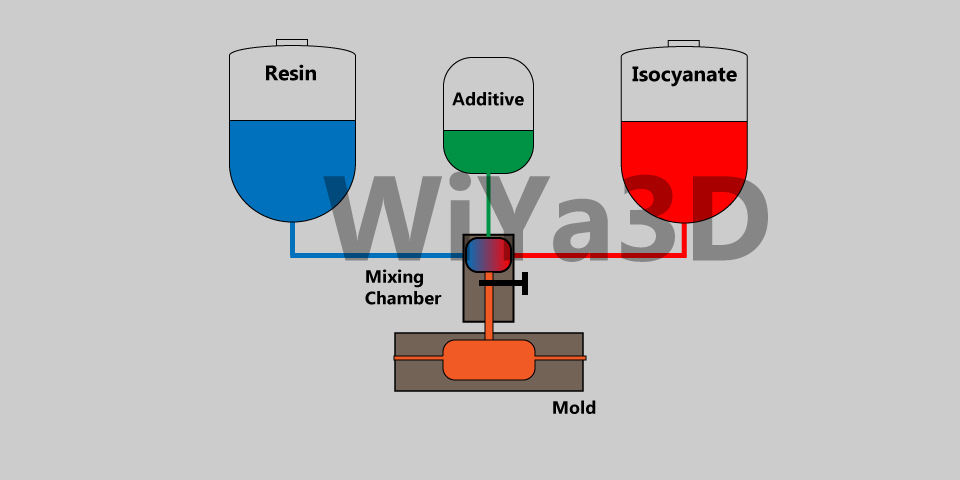

Vacuum Casting Technology

Vacuum casting is another casting technology that use to get exceptional surface condition and moisture defect free products. Mostly vacuum casting use for prototype development process in pre injection molded part with low volume development.

Once develop the master pattern for the casting with rapid prototyping, 3D printing, machining. The casting material (mostly silicon / silicon -rubber) pouring around the master pattern under vacuum condition. which produce casting mold and cure the casting mold and separate the two piece of cavity with parting line and remove the master mold.

The produce casting mold then again pouring with require molten material under vacuum and produce the copy of casting product in high quality.

Vacuum Casting Application

- Beverage Bottles

- Marketing Products Items

- Automotive Products

Defects In Castings

Internal Porosity or Voids – This mainly happen due to air entrap during material pouring and mold material flow incorrect. During pour the molten metal, the gas can dissolve in many liquid metal & those release with solidification of metal. Those rejected gas bubbles cause for the gas porosity. In order to overcome these kind of defect,

- This can mostly resolve melting the material under vacuum, using flux or within control environment condition.

- Removing the dissolve gas before pouring using vacuum degassing technique. Passing small inert/reactive gas through the melt material and allowing dissolved gasses enter with flushing gas and carrying away.

- Another method is adding additive material on molten metal and allowing to react with dissolve gas. Which produce law density compound that can later remove as slug.

Minimum Section Thickness – Casting cavity sectional minimum thickness also critical in archiving quality product. Molten material need to pass through all the cavity location before start solidification. If the certain thicknesses are obstacle, then it will cause part defect in many ways.

Non Filling of Critical Areas – This arise mainly due to incorrect mold design.

- Doesn’t provide quick molten metal/material flow inside the mold

- Due to gas entrap in certain location

- Insufficient molten metal temperature to compensate heat losses during material flow

- Improper mold reheating

Cold Shuts or Misruns – This defect mainly happen molten material start solidify before its reach the all the cavity location. And material flow over the already solidifying material which create layer with weak bonds.

Entrapment of Dross or Slag -This serious defect mainly happen oxide formation/slag flowing with molten metal and it gets entrap during solidification. Which lead weak internal location. This can be avoid by using proper fluxes.